Polymer liners for tank restoration are an innovative method of restoration of metal and concrete tanks.

Uncontrolled leakage of dangerous contents from steel tanks is a serious threat to the environment and human health, which inevitably leads to direct economic losses, as well as to expensive work to eliminate the consequences of pollution. Based on this, the legislation European The Union, as well as most other countries, requires equipping ground vertical tanks with a leak protection system.

- Versatility

- The technology is suitable for use on both metal and concrete tanks with a capacity of up to 380 m3, for a variety of liquid media (technological aqueous solutions, petroleum products, fertilizers).

- Economic benefits

- Restoration of the tank with the use of HDPE is 5-6 times more profitable than major repairs. No costs are required to replace worn-out steel sheets affected by corrosion. And under normal operating conditions, there are also no additional costs associated with servicing the tank from the inside. The dimensions of the inserts are determined by the internal dimensions of the tank structures, which allows you to optimize the costs of manufacturing HDPE.

- Minimizing product losses

- Leaks from the tank due to microcracks caused by deformation of the seams of the wall and bottom from "flappers" are excluded. The liner provides complete tightness: there is no watering and evaporation of the product (small and large "breathing" tanks).

- Efficiency

- All installation work is carried out in record time (from 3 days) and with minimal use of manual labor.

- Fire safety

- This technology does not require firing operations, which is especially important for oil refining or organic synthesis enterprises. It is also not required to issue permits for carrying out repair work.

- Mobility

- The design allows you to deliver HDPE to hard-to-reach areas with the lowest logistics costs.

- Durability

- The service life of the restored HDPE is extended for another 20 years.

- Environmental friendliness

- The HDPE used to restore tanks are chemically and biologically inert – they do not rot, do not decompose, are not affected by fungus, and do not affect the quality of the stored product.

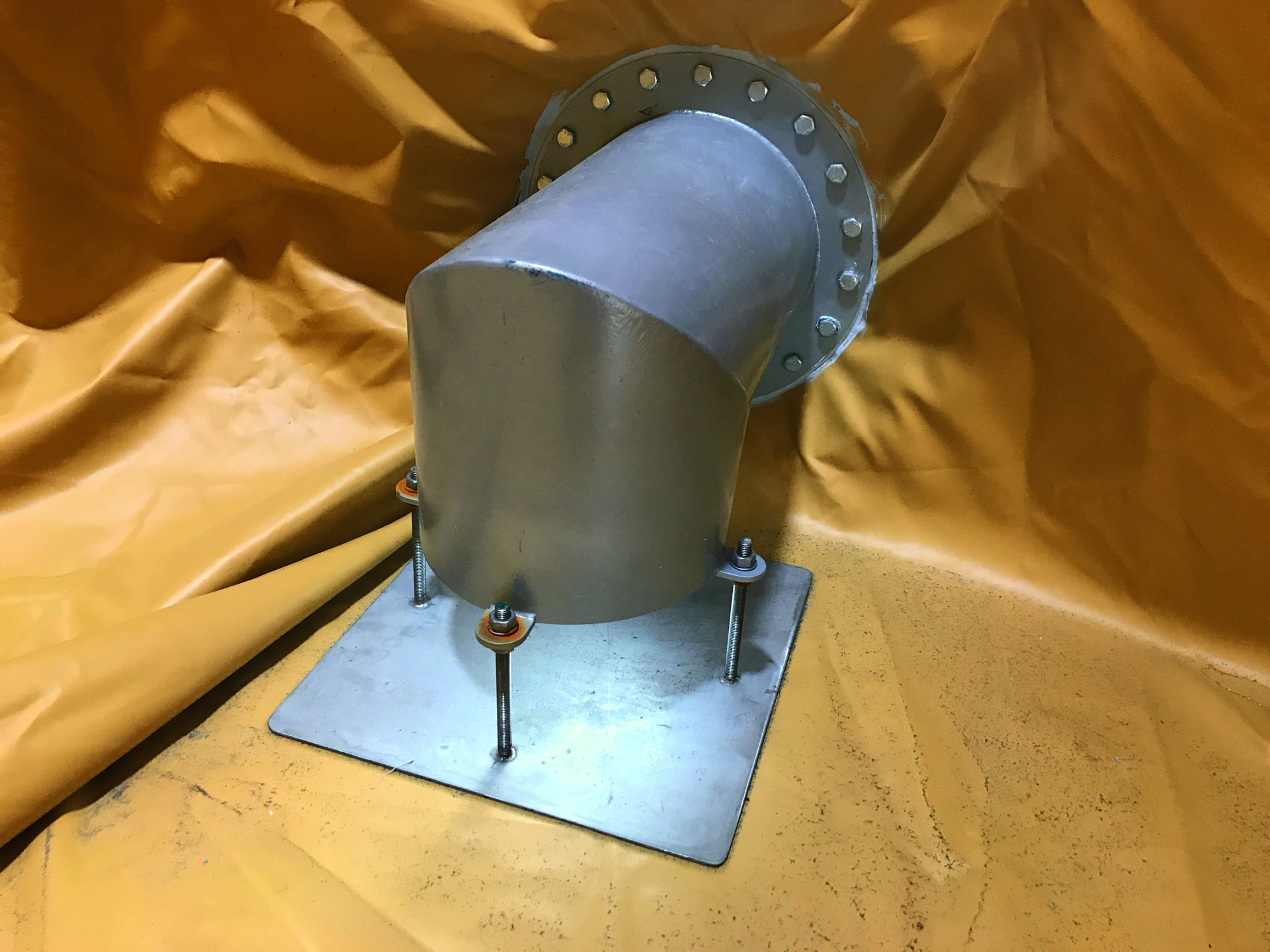

Equipping steel surface tanks of the VST type with elastic vacuum liners provides leakage protection for single-wall tanks at the level of protection of steel double-wall tanks with minimal time and money. The polymer layer of the liner is made of a polymer resistant to aggressive media, reinforced with a high-strength synthetic fabric of ballistic weaving. The properties of the polymer provide full protection of the bottom and walls of the steel tank from corrosion by aggressive agents of the contents.

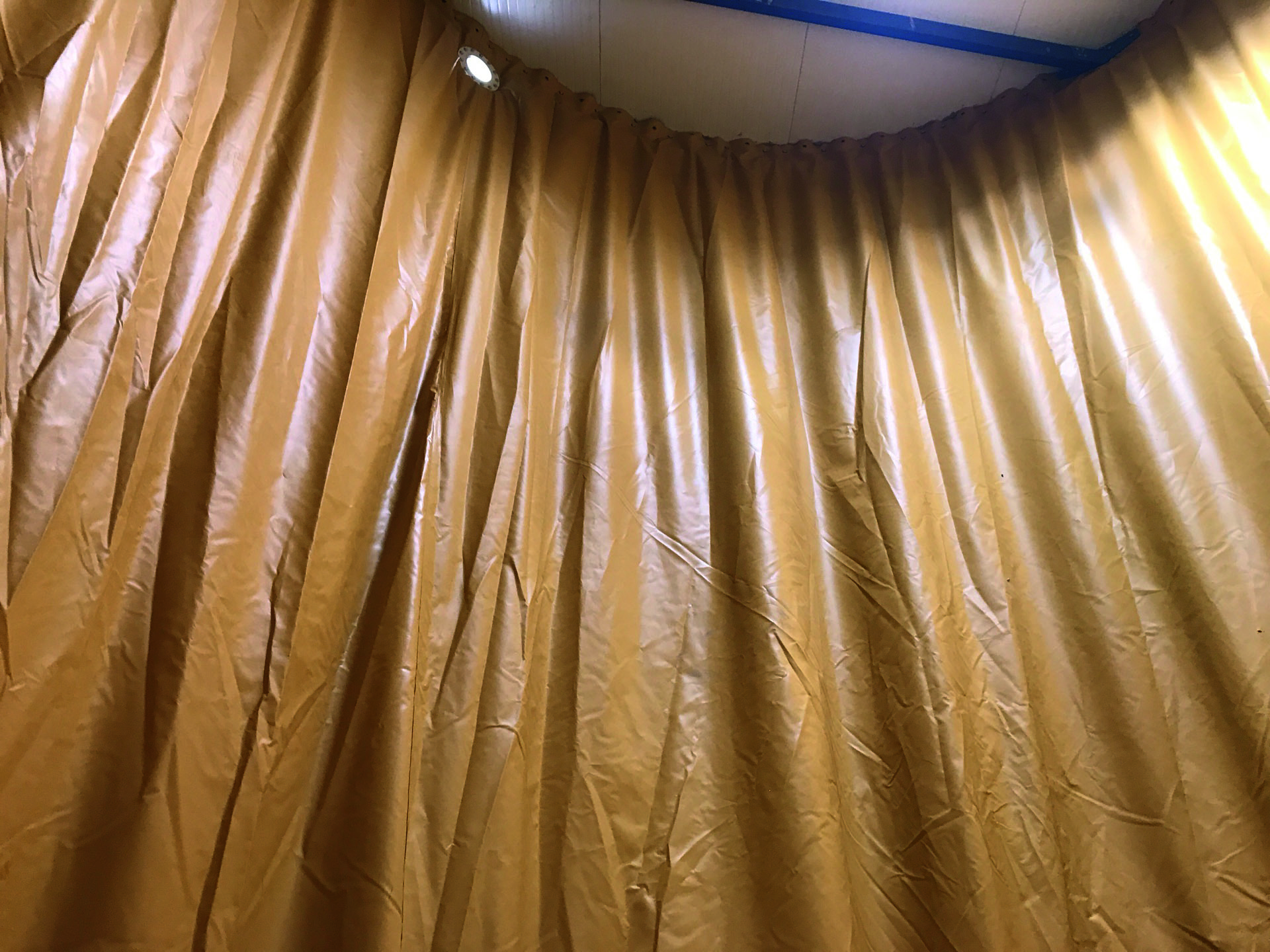

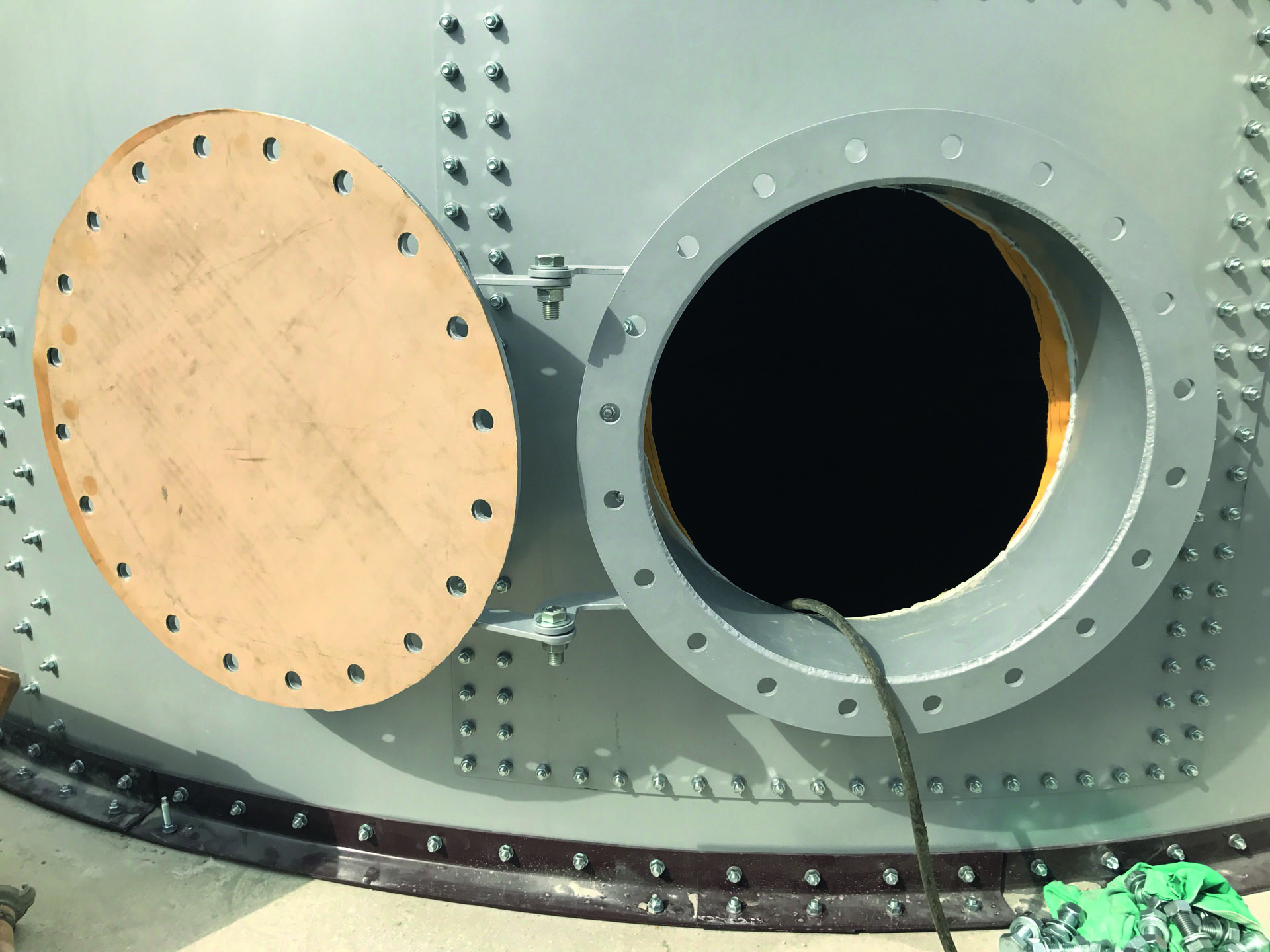

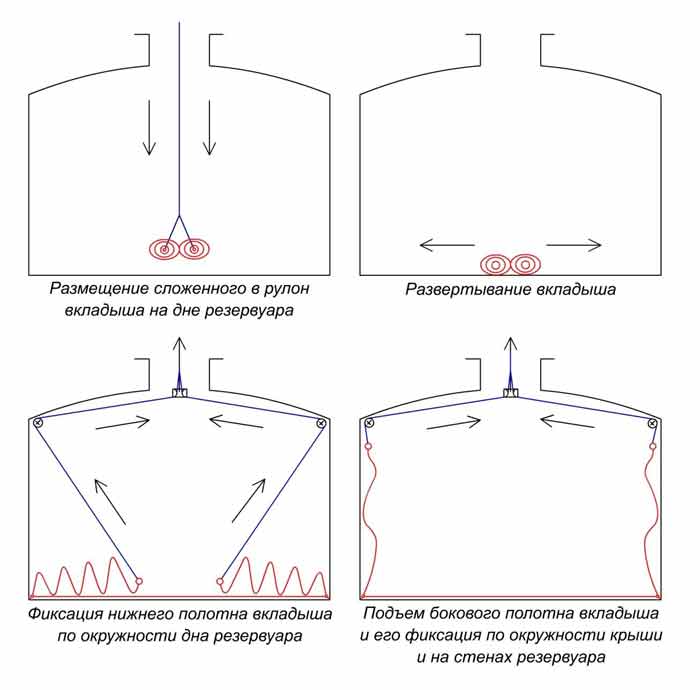

Elastic liners allow the use of conventional tanks made of “black” steel or concrete for the storage of drinking water, food and aggressive liquids, such as concentrated solutions of inorganic acids, salts, alkalis, liquid fertilizers, organic polar and non-polar solvents, including aromatic and aliphatic hydrocarbons.Elastic chemical-resistant liners are manufactured with a capacity of up to 50,000 cubic meters. made of high-strength polymer composite elastomers coated with PVC, TPU, PVDF, PVDC, LLDPE, HDPE, depending on the purpose, chemically resistant to a variety of types of aggressive media. The schematic diagram of the installation of a chemical-resistant liner in a tank of the RVS type, the installation of elastic inserts requires minimal labor and time and can be carried out both by the customer’s own forces and by a team of specialists from our service group. The sealed shell ensures an exceptionally long service life for both old and new tanks. The use of inserts allows you to practically eliminate leaks.

– cleaning of surfaces to the required extent (for example, by sandblasting), phosphating of the inner surface of the tank (creation by chemical means of an anti-corrosion film of insoluble phosphate);

– inspection of wall thickness by non-destructive testing methods for compliance with regulatory requirements;

– application of primer or polymer compositions (optional).